10 EASY STEPS ON HOW TO REALIGN A MOUNTAIN BIKE’S BENT DERAILLEUR HANGER

Derailleur Hanger Alignment In 10 Easy Steps

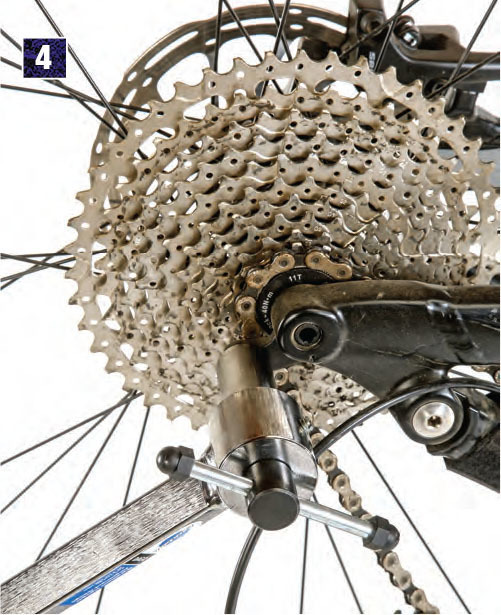

Nothing will derail your ride more than rear-derailleur problems. Shifting troubles can be extremely frustrating, mostly because the main source of the problem is often overlooked. When simple adjustments don’t fix your shifting woes, it’s time to check and see if your derailleur hanger is properly aligned. In order for your drivetrain to shift buttery smooth, your hanger must be aligned straight and true.

STEP 1: FIRST, CHECK THE BASICS

Before you begin tweaking your derailleur hanger back into position, first make sure that the hanger is actually the source of your shifting problems. Start by checking that your rear derailleur is set up properly, paying close attention to your B-tension screw and ensuring that your cables have proper tension. With modern 1x drivetrains, the upper pulleys on derailleurs don’t have as much axial play, allowing for quicker shifting but requiring more fine-tuning. If those adjustments don’t fix your problem, it’s more than likely you have a bent derailleur hanger.